CUSTOM MATCHING NETWORKS

You don't find an impedance matching network that fits your need? I can make it.

Here are some examples of custom matchers I made.

Multi-frequency Impedance Matching Network for a 500W Small Area CCP Reactor (13.56 + 27.12 + 40.68 + 54.24MHz)

I designed and built a complicated matching network for the Chair of Applied Electrodynamics and Plasma Technology at the Ruhr University Bochum in Germany.

This is multi-frequency matcher able to match simultaneously up to 4 frequencies. It can be mounted on a 19-inch rack with optional

brackets.

Driving radio-frequency capacitively coupled plasmas (CCP) by (non-sinusoidal) tailored voltage waveforms has been shown to allow considerable control over various plasma properties for surface processing applications.

A tailored voltage waveform (such as a "peak" waveform illustrated on the left) is synthesized by exciting a single electrode with a group of harmonics. The

impedance matching becomes therefore more complicated. Until now, this problem has been handled in research laboratories by using an oversized amplifier that can tolerate almost full power

reflection without any impedance matching network, thus limiting the applicability of this technique to very small/low power laboratory systems (<50W).

Two dummy loads simulating the customer's reactor were built and connected to the output of the matching network to test and validate the built circuit before shipping.

This multi-frequency matching network is based on a network of 8 LC resonant circuits. The inductors are fixed air core copper coils, and the capacitors are new variable vacuum capacitors. The 8 capacitors can be manually tuned from the front panel. A great attention was paid to the design and the placement of the various components to minimize the stray impedances and losses.

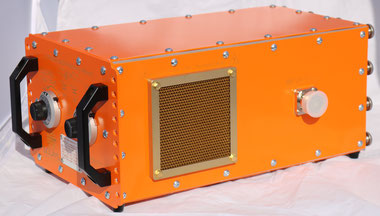

Impedance Matching Network for a 500W DBD Reactor (13.56MHz)

I designed and built for the Plasma Technology Research Center (PTRC) at the Universiti Malaya (Malaysia) a custom manual matching network for a dielectric barrier discharge (DBD) excited at 13.56MHz

The matching network should be able to perform the impedance matching up to 500W. The front panel was designed to ease the mounting on a 19-inch rack.

Three refurbished and tested variable vacuum capacitors were used to minimize the cost. The input and output RF ports, cooling air inlet and outlet were positioned to fit the customer needs.

Various capacitive dummy loads were built and connected to the output of the matching network to test and validate the built circuit.

A final plasma test was performed before shipping on a 13.56MHz CCP reactor up to 500W.

The series "tune" inductor can be modified at the back by removing a panel. This is needed in order to cover a wide range of load impedance.

Impedance Matching Network for a 400W VHF ICP Reactor (100MHz)

I designed and built for the Photonics Antenna Microwave Plasma group at ISAE in France a custom manual matching network for an inductively coupled plasma (ICP) excited at 100MHz in Argon for plasma-based antenna research.

The matching network should be able to perform the impedance matching up to 400W.

The customer provided the details about the geometry of the coil. I calculated the expected load impedance (without the discharge) including the coaxial cable at the output in order to design the most suitable matching circuit.

Three refurbished and tested variable vacuum capacitors were used to minimize the cost.

The input and output RF ports, cooling air inlet and outlet were positioned to fit the customer needs.

Various inductive dummy loads were built and connected to the output of the matching network to test and validate the built circuit before shipping.

Impedance Matching Network with a Wide Tuning Range at 2MHz (5kW)

I designed and built a manual high power matcher for an industrial company in India.

The circuit topology was optimized because the customer wanted for a R&D project to cover a wide range of load impedance either inductive or capacitive.

Three large refurbished and tested variable vacuum capacitors were used to minimize the cost.

The input and output RF ports, cooling air/water inlet and outlet were positioned to fit the customer needs. The RF output is at the bottom to connect the matcher

on top of the reactor. A cradle was designed to lift the matcher and protect the output connector during handling.

A custom water-cooled inductor was built. This inductor is adjustable by moving a tap to change the number of turns and the impedance matching range.

Impedance Matching Network for a 600W Large Area VHF CCP Reactor (13.56 to 81.36MHz)

I designed and built for the Plasma Physics Laboratory (LPP) at Ecole Polytechnique in France a custom manual matching network for a large area capacitively coupled plasmas (CCP).

The matching network should be able to perform the impedance matching up to 600W at four different RF frequencies: 13.56, 40.68, 60 and 81.36MHz.

The input impedance of the reactor (without discharge) was measured with a Vector Network Analyzer between 1 and 100MHz in order to design this optimized matching network.

Two refurbished and tested variable vacuum capacitors were used to minimize the cost.

The input and output RF ports, cooling air inlet and outlet were positioned to fit the customer needs. The RF output is on the top to connect the matcher below the

reactor.

The series "tune" inductor can be easily accessed at the back to modify its value before changing the excitation frequency.

Multi-frequency Impedance Matching Network for a 300W Small Area CCP Reactor (13.56 + 27.12 + 40.68MHz)

I designed and built a novel matching network invented by my customer: the Thin Films and Interfaces Laboratory (LPICM) at Ecole Polytechnique in France.

Two prototypes of a matching network (300W) able to match a CCP reactor simultaneously at 3 excitation frequencies (13.56, 27.12 and 40.68MHz) have been built to equip two different CCP reactors. Driving radio-frequency capacitively coupled plasmas (CCP) by (non-sinusoidal) tailored voltage waveforms has been shown to allow considerable control over various plasma properties for surface processing applications.

A tailored voltage waveform (such as a "peak" waveform illustrated on the left) is synthesized by exciting a single electrode with a group of harmonics. The

impedance matching becomes therefore more complicated. Until now, this problem has been handled in research laboratories by using an oversized amplifier that can tolerate almost full power

reflection without any impedance matching network, thus limiting the applicability of this technique to very small/low power laboratory systems (<50W).

This multi-frequency matching network is based on a network of 6 LC resonant circuits. The inductors are fixed air core copper coils, and the capacitors are refurbished variable vacuum capacitors to minimize the cost. The 6 capacitors can be manually tuned from the front panel. A great attention was paid to the design and the placement of the various components to minimize the stray impedances and losses.

The effectiveness of such matching network was demonstrated experimentally (see reference below) on a small area CCP Argon plasma. Under the plasma conditions studied, the power coupling efficiency was increased from less than 40% (without impedance matching) to between 80% and 99% for the different exciting frequencies.

Source: Wang et al. Journal of Vacuum Science & Technology A 37, 021303 (2019) https://doi.org/10.1116/1.5056205